by Isaac Record (University of Toronto), ginger coons (University of Toronto), Daniel Southwick (University of Toronto) & Matt Ratto (University of Toronto)

Abstract

Soon after Cody Wilson released his plans for the Liberator 3D printable gun, our Critical Making Laboratory undertook to produce a non-functioning version of the gun in order to assess the technical, material, and economic challenges associated with 3D printing proscribed objects. This paper recounts our experiences in creating the gun and analyses the disruptive implications of increasing availability of emerging fabrication technologies for regulation and regulators. 3D printing promises to upend traditional manufacturing by making complex, precision objects easy to produce. Plans are digital and can be duplicated and distributed over the Internet essentially without cost. 3D printers themselves, like their 2D namesakes, are general purpose machines with many legitimate functions, making their regulation a challenge. Some attention has already been paid to what regulators should do and to predicting what they will do. In this paper, we seek to explore what regulators can do. First, a conceptual framework allows us to assess the technological possibilities afforded by 3D printers. Second, we assess the increased regulatory challenge presented by this changed technological infrastructure. It is observed that much effective regulation is accomplished by technical, economic, ethical, and social constraints on action rather than by explicit legal proscription. For example, the high cost of precision machining and high level of technical skill required has traditionally been an effective protection against private individuals producing high-quality firearms ‘under the radar’. Low-cost 3D printers have the potential to allow for the near-effortless creation of precision parts, erasing this ‘contextual regulation’. This paper considers, in broad strokes, several possible regulatory targets: 3D printers, print materials, software, and the design file. For example, 3D printers could be licensed, materials could be watermarked, software could prevent the creation of certain shapes, or designs could carry increased legal culpability for damages or injuries. Against the potential gains to public safety, we weigh the potential costs of regulation that may 1) increase barriers to innovation, 2) unnecessarily restrict or complicate access to general purpose equipment, or 3) be unworkably costly in dollars and person-hours.

The Liberator

On May 5, 2013, Cody Wilson released the plans for the 3D printable “Liberator” pistol through his Defense Distributed website. On May 9, the US Department of State requested that he take down the plans while it determined whether Defense Distributed had violated the International Traffic in Arms Regulations. Defense Distributed complied voluntarily, but not before more than 100,000 copies of the file were downloaded (see http://www.forbes.com/sites/andygreenberg/2013/05/08/3d-printed-guns-blueprints-downloaded-100000-times-in-two-days-with-some-help-from-kim-dotcom/). The files now circulate freely on filesharing sites better known for pornography and cracked software. Our lab was one of the initial downloaders.

In the days following Wilson’s upload, a huge variety of claims and opinions circulated on the Internet and in the media. Wilson claimed that the Liberator rendered not only present-day firearms regulations, but also the very concept of firearms regulation, moot. Libertarians and anarchists valorized Wilson’s actions. Lawmakers around the country issued hasty statements: US Senator Chuck Schumer worried about ‘deranged individuals’ starting ‘gun factories’ in their garages. But one claim buttressed all of these reactions: anyone, anywhere, can now make a gun with very little effort as long as they have a relatively inexpensive 3D printer. There’s just one problem: it’s not true.

FIGURE 1: Setting the hammer on the modified Liberator

Why we built the Liberator

Why build anything at all? The Liberator is more important for what it symbolizes than for what it actually does. It isn’t a very good gun, in some respects worse than a ‘zip gun’ or ‘Saturday Night Special’ in terms of effectiveness, cost, and ease of access.

‘It’s already possible, if you want, to just go buy some pipes and put a gun together. This is another thing that I think has been conflated. People thought, ‘oh no this is the first time now people can expediently make guns.’ No; in fact, this is a very inexpedient way of making a gun, and kind of ridiculous. But it’s trying to be demonstrative and predictive of the future’ (Wilson 2013).

Likewise, in the US, where the gun was designed, well-functioning manufactured guns are relatively cheap and easy to find in both licit and illicit markets, including through weakly regulated private sale and the much-discussed ‘gun show’ loophole. But manufactured guns are regulated, at least in principle, and potential legislative and judicial actions have at least some chance of making existing laws more effective. And there is an important difference between zip guns and 3D printed guns: the design of a zip gun has remained essentially unchanged for decades, while the design of 3D printed guns is changing rapidly. The zip gun is a known quantity without much prospect for improvement. On the other hand, 3D printers are rapidly improving, and appear likely to continue improving in the near future. The likelihood is that better 3D printers will make better guns, perhaps even approaching the effectiveness, reliability, and safety of traditionally manufactured firearms. If that is true, then the Liberator serves as either a celebration or a warning. Firearms production may move to the privacy of the garage, rendering irrelevant current laws focused on controlling the distribution of manufactured weapons.

Just downloading the Liberator plans illustrates one of the challenges emerging technologies put to existing regulatory schemes. Our lab is located in a different country than Wilson’s Defense Distributed, and the laws in our jurisdiction are quite different from those in the US. In the US, the Second Amendment provides a presumptive right to produce firearms for personal use. In Canada, no such right exists. These differences alone were enough to make us wary of undertaking the project of creating a working firearm, and after a few attempts to interest law-enforcement agencies in supporting our research (they elected, perhaps understandably, to remain focused on active criminal investigations rather than fanciful, theoretical investigations), we decided to build a non-functioning version of the gun.

We set out to see just how hard it really would be for anyone, anywhere, to build the Liberator. Our previous experience with 3D printing suggested that creating an object as complex as a gun—even a relatively simple one like the Liberator—involves overcoming significant challenges. Our lab has a variety of 3D printers, ranging from hobbyist models costing a few hundred dollars to industrial models costing tens of thousands of dollars, making it an ideal setting for such an experiment. Would we discover unexpected and undocumented challenges? What expertise was required to overcome them? Furthermore, how good were the Liberator plans really—again, we wouldn’t be test-firing it, but could see how well the pieces fit together, whether the springs worked as advertised, and so on. The best way to answer these kinds of questions is to try it out.

There is another reason to build a gun rather than just talk about building a gun. We wanted to reflect upon the social, ethical, political, and legal issues that arose during the experience of planning and carrying out such a task. One limiting factor on action became much more salient through our experience: uncertainty about the legal and social acceptability of our actions. We were not certain about the legality of our actions, from downloading the plans to printing the gun. Moreover, there was uncertainty about our responsibilities should something go wrong in the construction and testing of the gun. Ultimately, these factors caused us to be more cautious in our plan of action than we might otherwise have been—and in the end, we built a nonfunctioning model so that it could never be fired.

Building the Liberator

Following the release of the Liberator files in May 2013, we began to consider the consequences of that act. While intended as an overt act of political subversion to protest gun control laws within the United States, in creating these plans, Cody Wilson was also contributing to a much larger debate about the implications of 3D printing’s ability to manifest data into physical objects, to democratize the manufacture of complex objects, and to disrupt the legal status quo across the world.

Much of the media attention that the Liberator garnered focused on warning audiences about the inherent dangers of 3D printing as a tool for allowing easy creation and distribution of guns and gun parts. To push back on this narrative our team felt it was necessary to build a Liberator to test the claims being made. Around the same time, we were invited to be a part of a television episode devoted to discussing the Liberator and its implications, and it was immediately clear that our conversations with law enforcement would not be completed in time for the airing of the television show (a request was made to test-fire the gun at one of the law enforcement facilities). This became the catalyst for building a non-functioning version of the gun. As mentioned, the legality of creating a functioning Liberator was unclear. Canadian law states that it is illegal to manufacture guns or gun parts, but how this applies to 3D printed guns was, to the best of our knowledge, untested. Also, we were primarily interested in investigating claims about the difficulty of printing and assembling this object, so a working model was not necessary.

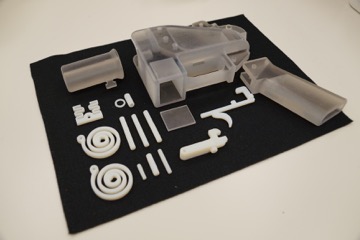

Once it was decided to move forward with a modified, non-functioning Liberator, the question was how to modify the design. It was ultimately decided to print our version with the Object 30 pro using clear resin. This material would not have the same properties as the design called for—in particular, it would be more fragile—but by printing in clear we would be able to easily highlight specific parts of the gun. In addition, we countermanded several of the print instructions, printing the barrel and the hammer springs in a different orientation so that they would not have the tensile strength to function as designed. Finally, we filled in the hole for the firing pin by gluing a plug in place. This would prevent anyone from ever placing a firing pin in our Liberator, and effectively rendered it completely inoperable. The initial print took 17 hours and cost approximately $450 CDN.

Figure 2: Modified Liberator being printed

In the final hour of the print the drawer containing the resin was mistakenly opened, halting the print temporarily. This resulted in a minor split that runs the entire length of the central body piece. If the aim were to create a working model, it would have meant starting over, but since this was not our concern, we went ahead with the flawed print.

With all of the pieces now successfully printed, there was a post-production process to remove support material and ensure that edges were smooth. The specifics of this process vary from printer to printer. In the case of the Objet 30 Pro, it involved 4 hours with a power washing hood plus an additional hour cleaning the pieces with rubbing alcohol to remove the final remnants of the support material.

With the pieces prepared, it was finally ready for assembly. While one of us read the instructions aloud, another snapped the pieces together. The process was relatively straightforward, requiring approximately the same amount of skill as assembling furniture from a kit. However, there were a few stumbling blocks: the orientation of the springs was not made clear in the instructions. After snapping them on for the first time, it became clear that they were backward. When we tried to remove the piece, parts of the body flaked off, leaving a noticeable piece of the firing pin casing damaged. Once the spring had been removed and placed on correctly, there was trouble inserting several of the pieces into the body, presumably because the tolerances were too tight. Light sanding corrected that problem, but slightly marred the clear finish.

Figure 3: All of the pieces, ready for assembly

With the finished product finally in hand we began to review the processes that had led to its creation. What struck us first was the sheer size of the infrastructure needed to manufacture the object. It took two PhD students and a post-doc the better part of three days to make the object. In making it they had engaged with tens of thousands of dollars worth of equipment, each piece with its own supporting infrastructure. To us, this served as a clear demonstration that the act of making a Liberator remained, for the moment, impracticable for most people, for lack of access to equipment and expertise. Finally, everyone who worked on the project at one point or another commented on how rudimentary the Liberator was, in terms of both functionality and feel. None of us felt comfortable with the idea of test-firing the object by hand.

Putting 3D into context

3D printing and other emerging technologies stand to disrupt on several levels: intellectual property, production and distribution, safety and regulation, and responsibility and credit. Increasing availability of 3D printers allows distributors and consumers to appropriate production processes or conception, design, manufacture, and assembly (Cf. Troxler and van Woensel 2013, p. 199: ‘…change of where manufacturing actually takes place…’). Plans are digital and increasingly completely specify artifacts. These plans freely cross between legal jurisdictions, yet 3D printers themselves, like their 2D namesakes, seem to classify as general purpose machines, capable and perhaps primarily used for perfectly legal activities. All of this poses a special new challenge for bodies seeking to control the manufacture and distribution of dangerous goods. Some attention has already been devoted to the question of what government should do and to predicting what it might do. In this paper, we seek to explore what government can do with the view that regulation works as a cost-benefit balancing act in which certain possible actions are restricted because of the risks they pose. 3D printers vastly increase the number of possible actions achievable at the scale of the individual or private group. At the same time, the technological infrastructure surrounding them, especially the Internet, vastly decreases the power of government to effectively control certain features of 3D printing manufacturing. Our case is made in three parts. First, we lay out a conceptual framework that allows us to assess the technological possibilities afforded by the increasing availability of 3D printers and the technical infrastructure surrounding it. Second, we assess the increased regulatory challenge presented by this changed infrastructure. We observe that much practical regulation is in fact accomplished in part or whole by technical, economic, ethical, and social limitations rather than by legal intervention per se. For example, the high cost of precision machining has traditionally been an effective protection against private individuals producing firearms ‘under the radar.’ Low-cost 3D printers have the potential to allow for the creation of precision parts, erasing this ‘contextual regulation.’ In order to understand the complex interactions among formal and contextual regulations, we introduce the idea of the ‘action landscape.’

Action landscape

This paper focuses on the prospects for legal regulations of emerging technologies, but before discussing legal alternatives in detail, it is important to briefly describe some of the factors that contribute to or militate against the effectiveness of such regulations. As already stated there a variety of factors that encourage certain actions in particular contexts while discouraging others. Lessig (2006) has made a similar observation with respect to Internet technologies, identifying four modalities of regulation: legal restriction or prohibition; social norms; market or economic factors; and architecture, which is meant to capture the way a system’s design and implementation constrain user behaviors (See Lessig 2006, Chapter. 7). An important difference between Lessig’s account and ours is that Lessig is focused primarily on methods by which institutions can and do shape the online world, while we are focused on identifying factors that can and do shape individual actions. That is, our account encompasses the factors Lessig identifies, but goes beyond them by including individual capacities and by focusing on a broader set of activities. Like Lessig, we wish to consider how these factors interact, and like Lessig, we worry that ‘law-talk typically ignores these other [constraints on action] and how law can affect their [functioning]. Many speak as if law must simply take the other … constraints as given and fashion itself to them’ (Lessig 2006, p. 126).

Our research regards regulations and other constraining affordances as making up a kind of ‘landscape’ in which actors can consider various actions. Similar to the ‘fitness landscape’ of evolutionary biology, the purpose of the metaphor is to make it easier to visualize the relationships between contextual and legal factors. In our ‘action landscape’ the idea is to compare the ease with which an actor can move from one situation or position to another across a landscape shaped by various constraining affordances such as laws, technological possibilities, economic considerations, depending on capabilities and resources such as brute effort and cognitive abilities. It is not our intention to formally model or quantify these interactions; rather, we simply want an easily accessible metaphor that allows us to think through the interactions between different constraining affordances.

We can begin by considering the case at the centre of this paper. An individual wishing to produce a firearm prior to 3D printing faces a number of barriers or impediments: the necessary equipment is expensive, the skills are difficult to master, and legal strictures place limits on the type of firearm to be constructed and under certain circumstances may prohibit the sale of the product. Each of these factors contributes to make it an uphill battle to create a working firearm. The combination of barriers is often a more effective impediment than any one of them alone, though typically they do not simply ‘add up’ in a linear fashion. Sometimes they reinforce one another, other times they act to cancel each other out. After 3D printing a firearm became possible, several of these barriers to firearms manufacture changed. The cost of necessary equipment decreased. The skills shifted from the difficult-to-acquire skills associated with machining to the relatively ubiquitous skills associated with finding and downloading a plan on the Internet and (ideally) pressing ‘print’ on the 3D printer control software. The legal restrictions have, so far, stayed constant. But because the other barriers have been lowered, there is cause to revisit firearms legislation to determine the prospects for (and desirability of) re-establishing an equilibrium close to the current status quo.

At the outset, it is possible to distinguish between internal factors that ‘belong’ to the actor and external factors that ‘belong’ to the landscape. Actors have particular material and cognitive capabilities and resources at their disposal and these internal factors together define the set of possible actions for the actor in a given situation (see Record 2013). External factors, like social norms, legal strictures, and physical possibilities make up the context or landscape in which the actor is embedded. For example, the architecture of typical 3D design software makes it relatively easy to create using straight lines and regular curves, but difficult to create using organic shapes. Laws can make it more or less difficult to access the equipment at all. These external factors can interact. For example, a law could require a change in the architecture of 3D printing process that would make the creation of certain kinds of shapes with certain kinds of material properties difficult or impossible to form. In addition, actors can effectively change the difficulty of the ascent by changing their own situations ahead of time. For example, a person can change her internal factors by mastering difficult manual or cognitive skills. She also has some control over how external factors apply to her. For example, she can move to a different legal jurisdiction or save up enough money to buy or rent previously unavailable equipment. In addition, external forces can alter the landscape and change what is possible for a particular actor. For example, laws and social norms can change and more effective or less expensive technologies may be developed. An actor with skills and resources that are well-suited to one legal-social-physical situation may find it harder to make her way in a different situation because those skills and resources are not appropriate to the changed conditions.

Within an action landscape, we can further distinguish between ‘formal’ or ‘maintained’ regulations and ‘natural’ or ‘environmental’ barriers to action. Formal regulation can create, limit, or constrain opportunities for action. Regulation can take on a number of forms: governments create legal regulations, contracts create agreements between parties, industries self-regulate, social groups create and enforce norms, and so on. The boundary between formal and contextual regulation is fluid and permeable. Some of the most effective regulatory actions take advantage of the interplay between maintained and natural barriers to action. Traffic calming speed humps cross from one to the other. Speed limit signs inform drivers of legal limits, but do not themselves enforce the limit. Something additional is required to enforce the limit. A driver’s internal ethic to obey laws can result in compliance or police patrols can help to maintain adherence to the speed by adding undesirable consequences to a breach. But these are forces outside of the sign itself. Speed humps, on the other hand, actively encourage adherence by creating direct consequences for an infraction: violators risk physical discomfort or damage if and only if they speed over the hump. The key distinction between formal and natural constraints is that formal constraints have to be enforced by an additional regulating body like a police force, while natural constraints influence behavior by their structure or material form. Formal regulations typically require an ongoing investment of resources to construct, monitor, maintain, and enforce, while natural constraints—even those that are constructed and maintained, like speed humps—become a part of the infrastructure or environment. (Thanks to an anonymous referee for asking us to clarify this example.)

Before going on, it is important to emphasize that there is a distinction between how the landscape appears to a given individual who is embedded within it and what the landscape is really like. A bold actor may choose to make an ascent against all odds if the predicted benefits are good enough. But even cautious actors can be fooled by appearances. Like real landscapes, distant peaks sometimes appear closer than they really are, encouraging us to set out upon a path that in reality is full of hidden pitfalls and other difficult terrain. On the other hand, some paths look very difficult or dangerous when in fact there is a hidden path straight to the summit. For the most part, the distinction between appearance and reality in this paper (or ‘possibility’ and ‘live possibility’) will be ignored, but it is important to note that the reality of imperfect information and imperfect decision making skills will complicate matters in real life.

We also want to acknowledge that ‘landscape’ is not a perfect metaphor. For one thing, there are too many constraining affordances to be adequately represented in three dimensions. In addition, legal or social landscapes can change quickly, while real landscapes typically change on a geologic timescale. Furthermore, it isn’t clear that geologic features are necessarily the best metaphors for, say, legal barriers. Perhaps these would be better represented by walls, gates, paths or other ‘human scale’ features. However, it is important not to become too caught up in the metaphor. The two important features are: (1) the interaction between the many and sundry factors and (2) the distinction between qualities of the actor and qualities of the landscape.

In the following sections, the paper will briefly discuss internal factors, such as cognitive and physical abilities and ethics and motivation. Then we will turn to external factors, including ‘natural’ or ‘contextual’ factors like material resources, availability of training, and access to technology. Finally, the paper will discuss in somewhat greater detail some formal or legal interventions starting with those specific to the case of 3D printed guns and then moving to more general concerns for 3D printing, including intellectual property and liability law.

Internal Factors

Technical skills and training

One factor individuals have some control over is skills and training. Individuals can enroll in formal classes, informal training programs, or can find guidance online. For example, basic CAD skills are taught at vocational schools and community colleges. Maker spaces often have training programs to enable newcomers to become familiar with their equipment. And online resources include ‘how to’ websites like Instructables and a multitude of video tutorials created and shared by interested amateurs—and even some professionals. Gaining skills and training requires a combination of cognitive ability, motivation, and motor skill, as well as an ability to translate exercises into the specific skills needed to make use of particular equipment. Depending on the specific skills or training required, individuals may also face monetary hurdles: software licenses and credentials can form a very costly barrier to entry. There is some prospect for governments or other organizations to regulate the availability of needed skills through licensing or accreditations schemes, but there presently exist many open educational resources for gaining and sharing this knowledge.

Ethics

Personal ethics are a strong determinant of behavior. People often take action because they believe it to be the right thing to do, and they often refrain from acting in contradiction to their personal ethics. Of course, people can be swept up in mob behavior, or may have trouble resisting temptation under the right circumstances. But when regulation can tap into existing ethos, it can curtail occasions of deviance. Personal ethics have a complex interaction with regulation. In cases where the two align, a desire to uphold the law can be more of a deterrent than the law itself. On the other hand, when personal ethics and the law are vastly mismatched, the result can be disastrous. Music sharing is one example of this. In the early days of music downloading, the music industry pursued copyright violators well beyond what many young people believed was reasonable. For some, this perceived injustice, in which the punishment was out of proportion to the crime, served to invalidate the original claim of harm. Downloading was transformed for them into a rebellion against a corrupt establishment, and rendered a peaceful solution all but impossible. Ultimately, the conflict between personal ethics and perceived bullying by the music industry transformed into a shared community norm of downloading among people of a particular generation.

Uncertainty

Another potential barrier to undertaking a particular action, like 3D printing a gun, is the legal and ethical uncertainty surrounding it. Unlike manufacturing in a traditional setting, where legal issues of liability are relatively well understood by practitioners (usually corporations), the legal culpability for injury or malfunctioning product is not as clear for hobbyists. To a large extent, caveat emptor seems to rule the day, but it is certainly a worry that anyone selling 3D printed artifacts might be open to lawsuits if the artifact breaks. Indeed, in our own experience printing the Liberator, it was worry over the legal status of the object that caused us to think twice before trying to print it, and these worries ultimately prompted us to alter the design of the gun so that the object we ended up printing could never function as a weapon.

Issues of safety and legal culpability are not new. They accompany many traditional modes of creation and sale. A carpenter who builds a faulty shelf is culpable for the failure. But there are two aspects of emerging technology that make these issues especially uncertain. First, when technologies disrupt traditional modes of design, manufacture, sale, and distribution, it is not always clear how existing laws will apply. Second, because emerging technologies are often adopted by individuals who are not familiar with existing legal systems, uncertainty may play a larger than typical role in deciding whether an individual pursues a perceived opportunity to create a new product. And third, because 3D plans can be shared over the Internet, they may cross legal boundaries and affect many more people than typical craft items.

Although individual response to uncertainty is an internal factor, governments and other groups can do much to reduce uncertainty. By writing clear legislation and publishing guidelines for the application of existing law to emerging technology, governing bodies can greatly reduce the kind of uncertainty that stifles innovation. We will have more to say on this point later.

Contextual Factors

Equipment

Perhaps the most obvious barrier to using emerging technology is physical access to the technology. A 3D printing firm took back equipment from Cody Wilson once they learned of his plans to print a gun. Although hobbyist 3D printers are now widely available (via numerous Kickstarters, MakerBot Industries, and even some retail locations), highly capable 3D printers remain out of reach for most consumers due to cost. For example, 3D printers that produce metal objects are prohibitively expensive for most individuals or small businesses.

It is conceivable that governments could add to the existing access barrier by requiring 3D printer manufacturers to maintain a record of individual sales. They could also outlaw or regulate resale of 3D printing equipment. Or they could require owners of 3D printers to be licensed (just as handgun owners have to have a license in Canada and the US). Cory Doctorow, a journalist and author who has written extensively on 3D printing, has expressed concern that ‘the fact that we’re talking about guns here will cloud judges’ minds’ and cause them to set precedents that could reach beyond personal firearms manufacture and 3D printing to the Internet itself (Doctorow 2013).

However, it is not clear how effective government attempts to restrict access to 3D printers might be, not least because the parts and know-how to build a basic 3D printer are already widely available. The availability of open-source 3D means that regulating 3D printer manufacture may not be sufficient to control 3D printing. RepRap is an open-source project based in the UK that aims to create a free 3D printer that can reproduce itself. Current models can print all of the plastic parts of the printer, leaving only off-the-shelf circuit boards, motors, and some standard fasteners to be acquired separately. Because these parts are general in purpose, there is virtually no prospect that they could be effectively regulated. Two other projects, Fab@Home out of Cornell University and MakerBot Industries, have also contributed to the open source hardware community.

At present, then, consumers have ready access to hobbyist 3D printers, which are already capable of producing the Liberator. The costs range from a few hundred dollars (plus a large amount of specialized skill and time) to a few thousand dollars for a consumer model that is ready to print out of the box. Much more capable machines can be found used or refurbished for tens of thousands of dollars, and highly capable machines capable of creating fine metal guns can be purchased for hundreds of thousands of dollars. Machines can also be rented at considerably lower costs, and some rental models allow customers to remove the equipment to their own property, where secrecy can be guaranteed. Typically, this is out of legitimate concern to protect trade secrets, but it could also be used to produce illicit goods.

Community norms

Community norms are related to personal ethics (discussed earlier). Norms can be internalized as ethics, and individuals can promote their ethics as norms. However, community norms are distinct from personal ethics. Norms are shared and socially enforced, while ethics are private and internally enforced. Community norms can be a surprisingly effective method of controlling the use of emerging technology.

First, people tend to be introduced to technology through work, school, or through friends. That is, people are most likely to encounter technologies that are already in use within their communities. Filesharing, for example, made its way into the public consciousness by way of college campuses, where Internet connections were fast and reliable and where there was a gathering of tech-savvy computer users. Now the practice is widespread, and in many communities is considered an acceptable practice despite copyright laws to the contrary.

Second, Maker spaces and associated online communities often have a shared commitment to maintaining a safe environment for learning and sharing. This means that communities sometimes resist members who threaten to stir up trouble by sharing designs of infringing or potentially dangerous objects. Makers often have a “live and let live” attitude, but they can be fiercely protective of their physical and online spaces. Websites like Thingiverse have explicit policies requiring that users upload only content that they own, and that the objects be legal, non-pornographic, etc. In addition, they have instituted take-down policies that allow members or intellectual property owners to report when a member abuses these terms of service. The object can be removed and the person banned from the site.

Third, people dealing with emerging technologies often discuss their concerns about it with other members of the community, and often this is how potential risks and rewards are discovered, catalogued, discussed, and resolved. This is especially the case for technical issues, but applies also to ethical, legal, and safety concerns. As Eric S. Raymond puts it, ‘given enough eyeballs, all bugs are shallow’ (2000). Raymond is arguing that one advantage to a large group of cooperating developers is that virtually any problem that is encountered can be solved by someone. That is, among a large enough population, someone will have both the skill and the interest to fix the problem. Raymond was speaking explicitly about software bugs in the development of open-source software, but the lesson generalizes: the larger the population of users, the more likely it is that a problem will be exposed and the more likely it is that someone within the group will have the interest and skill to solve the problem.

Policies and legal restrictions can strengthen social norm constraints. Governments seeking to regulate 3D printing would do well to work with existing communities of users and to add legal force to existing norms rather than simply legislating from on high.

Formal Regulation

In the following, the paper considers two categories of formal regulations that could apply to 3D printing. The first would target 3D printed guns, and the second would apply to intellectual property. Emerging technologies ‘exist in legal and social gray areas, as we struggle to determine what role we want them to play in our lives and what level of regulation is necessary to define that role’ (Zimmer 2013, p. 251). Regulators need to tread a careful line between protecting the public and stifling creativity. Almost by definition, regulating emerging technology is a challenge. Emerging technologies disrupt not only regulation but also some of the contextual factors that current regulation may assume to be stable. Prediction under such conditions is a fool’s game, but there are precedents we can learn from.

Firearm regulation

Cody Wilson created Defense Distributed and the Liberator with the express purpose of making firearm regulation impossible. According to some analysts, he has already succeeded. Jensen-Haxel, for example, claims that ‘3D printers will render current firearm regulations obsolete by allowing individuals to easily produce firearms—production that, when exercised by law-abiding citizens, may be protected under the Supreme Court’s decision in District of Columbia v. Heller’ (Jensen-Haxel 2012, p. 448). Our analysis of firearm regulation will focus on the United States, with its constitutional protections for firearm ownership and enormous market for guns (four and a half million new guns are purchased each year in the US, accounting for over half of the world’s annual production). Despite our focus on one legal jurisdiction, we expect our analysis to be relevant to jurisdictions around the world. This is because 3D printing technology, in conjunction with Internet-enabled file-sharing, makes legal distinctions between jurisdictions increasingly irrelevant to individuals, so that plans for the items that are accepted in the most liberal (or unpoliced) jurisdictions are easily transported to more restrictive jurisdictions, where they can be manufactured privately using 3D printers. This goes for sex toys in Alabama, guns in Canada, and copyrighted materials anywhere. 3D printing makes it easier for individuals to skirt the laws in force in their own jurisdictions (see O’Neill 2012 for further analysis). This worry has recently been substantiated by the first publicized arrest for alleged possession of illegal weapons that were created using a 3D printer. Yoshitomo Imura, a 27-year old man from Yokahama, Japan was arrested on 8 May 2014 for possession of five guns, including a Liberator[1]

This incident suggests that the impact of 3D printing on existing regulations may be greatest outside of the United States, where firearm regulation is often more stringent and social attitudes less accepting of guns, making it much more difficult for individuals to acquire or possess them.

Did we break the law when we printed our modified Liberator in Canada?

In Canada, without an appropriate license, it is prohibited to manufacture or transfer (or to offer to manufacture or transfer) a firearm. Ownership of a firearm, without a license, is also prohibited. A firearm is defined in section 2 of Canada’s Criminal Code as a ‘barrelled weapon’ capable of discharging ‘any shot, bullet or other projectile…that is capable of causing serious bodily injury or death to a person’ (Ministry of Justice 1985). The definition of a firearm also ‘includes any frame or receiver of such a barrelled weapon and anything that can be adapted for use as a firearm’ (Ministry of Justice 1985) which is a somewhat broad mandate. However, section 84 of the Criminal Code sets forth a definition of a class of tools which are explicitly not firearms, namely: barrelled weapons which can be proved to be ‘not designed or adapted to discharge (i) a shot, bullet or other projectile at a muzzle velocity exceeding 152.4 m per second or at a muzzle energy exceeding 5.7 Joules, or (ii) a shot, bullet or other projectile that is designed or adapted to attain a velocity exceeding 152.4 m per second or an energy exceeding 5.7 Joules’ (Ministry of Justice 1985). The section also specifies that devices which are designed to fire projectiles such as rivets or other industrial materials are not classified as firearms, insofar as they are used for their designed purpose. As such, according to Canada’s Criminal Code and the associated provisions laid out in the Firearms Act (Ministry of Justice 1995), the device we produced cannot be classified as a firearm, first because it does not meet the functional requirements of a firearm (it cannot fire a projectile with adequate force to do serious harm to a person) and second because it is explicitly designed to be unable to fire a projectile at adequate speed.

A second concern which could be leveled against a non-functional version of the Liberator might be that it contravenes the Criminal Code’s restrictions against what are termed “prohibited devices.” This class of object includes replica firearms. A replica firearm, according to section 84 the Criminal Code, is “any device that is designed or intended to exactly resemble or to resemble with near precision, a firearm, and that itself is not a firearm” (Ministry of Justice 1985). This provision opens up a comparatively interesting possibility for the 3D printing of firearms. Though the Liberator does not closely resemble any known firearm, and though the device printed in the Critical Making Lab makes it very clear, by dint of its transparent plastic construction, that it is not meant to resemble a firearm, the advent of short-run firearms produced in small batches using desktop fabrication technology makes it eminently possible that the class of objects which closely resemble firearms might become far broader than it currently is.

Firearm regulation in the United States

Firearm regulation targets the manufacture, sale, and ownership of firearms. ‘A person manufacturing firearms is “engaged in the business” if he or she “devotes time, attention, and labor to manufacturing firearms as a regular course of trade or business with the principal objective of livelihood and profit through the sale or distribution of the firearms manufactured.”’ 18 U.S.C.A. § 921(a)(21)(A) (Westlaw 2012). The definition is similar for dealers and importers. ‘Principal objective of livelihood and profit’ means ‘the intent underlying the sale or disposition of firearms is predominantly one of obtaining livelihood and pecuniary gain.’ 18 U.S.C.A. § 921(a)(22) (Westlaw 2012) (Jensen-Haxel 2012, pp. 456-57). In this way, the government aims to control what guns are available to the public and to whom they are available. Typically, the frame of the gun is controlled, while other parts can be replaced without a separate license. The practical reason for this is that the frame is a precision engineered part that lends itself to control. Manufacturers stamp a serial number onto each frame, sellers register the owner of each frame, and the results are fed into a database that law enforcement officers can access. In addition, some regulations apply to the modification of firearms, for example making it illegal to alter a (legal) semi-automatic weapon to make it an illegal fully automatic one. “The cornerstone of this system, then—the unspoken assumption—is that the frame is difficult for an ordinary person to make” (Jensen-Haxel 2012, p. 464). Yet this is precisely what 3D printing threatens to change. One the one hand, traditional firearm manufacturers are designing plastic frames. And on the other, consumer grade 3D printers are increasingly capable of reproducing precision parts. Cody Wilson’s Liberator may be ahead of the curve in certain respects, but it is a clear harbinger of things to come.

The legality of home manufacture

In the United States, firearm regulation targets industrial manufacture of firearms. This is the type of activity that requires a federal firearms license. With very few exceptions, ‘individuals who produce guns for personal use fall outside the major regulatory system; they are not required to be licensed, as they are not “engaging in the business” of manufacture’ (Jensen-Haxel 2012, p. 459). One exception is the 2003 conviction of Robert W. Stewart, who made five homemade machine-guns (United States v. Stewart, 451 F.3d 1071, 1072-73 (9th Cir. 2006)). Machine-guns violate the National Firearms Act, which aims to reduce the use of certain kinds of weapons, like sawed-off shotguns and machine-guns, in crime. Until recent years, the legality of home manufacture has not been a serious concern for public safety advocates, because making guns was difficult. Some criminals have built their own guns, but they are generally as dangerous to the shooter as the target (see Jensen-Haxel 2012, p. 462). In our estimation, the 3D printed Liberator does not presently surpass such improvised weapons (‘zip’ or ‘gadget’ guns) in reliability or efficacy, but as designs and 3D printers advance, that balance is shifting. In theory, gun enthusiasts have always been able to make their own guns, but in practice this has required expensive metalworking tools and exacting skill. With the advent of precision 3D printers, both the cost and skill barriers shrink considerably. As O’Neill (2012) puts it, ‘3-D printer technology democratizes the process significantly. In addition, ‘by linking the firearms modeling to universal CAD software, the interchangeability of plans and their continued perfection is unlike anything seen with handcrafted weapons’ (O’Neill 2012, p. 5). The capacity to build upon existing designs means that the journey from the somewhat improbable Liberator to a sophisticated weapon may be very fast, and the result may be available to almost anyone at very low cost.

The worry over 3D printers and guns extends beyond worries about fully printable guns like the Liberator. Firearm regulation in the US relies on controlling the frame of the gun. On 20 September 2011, a digital blueprint for an AR-15 assault rifle frame was uploaded to Thingiverse (Thing #11669) (see Jensen-Haxel 2012, p. 456). There are at least two reasons to think that fears about 3D printed frames are well-founded. First, plastics are seeing increasing use by traditional gun manufacturers. Second, firearm design is likely to take advantage of the new affordances of additive manufacturing to literally reshape guns, perhaps radically. Consequently, Jensen-Haxel recommends that firearm regulation shift from the frame to another essential gun component, such as the rifled barrel. Even this seems as though it may only delay the inevitable.

The Liberator’s barrel is made from plastic, and in our estimation this is a significant limitation to the effectiveness and reliability of the weapon. There is a reason the Liberator is a .38 (o.38” barrel opening) and that the barrel is only 2.5” long. A larger caliber bullet or longer barrel would likely result in explosive malfunction of the gun. Even as is, Wilson recommends that each removable Liberator barrel be used only once, and his own tests have confirmed that they warp and deform enough to appear dangerous after a handful of shots. The ATF has released a slow motion video of the barrel exploding during a test fire at one of their facilities (see: https://www.youtube.com/watch?v=ZL7y3YNUbiY). Barrels need to withstand the acute pressure of exploding powder and they have to be precisely machined to contain but not obstruct the bullet as it traverses the length of the barrel. This pressure can exceed 50,000 pounds per square inch—well beyond what typical consumer grade printers can make out of plastic (see Kolbe 2000). However, as 3D printers improve or designs change, it may become increasingly practicable to 3D print barrels.

The most straightforward response available to lawmakers is to criminalize the act of making guns, perhaps narrowly constrained to specific processes like 3D printing or to specific materials like plastics (see also Jensen-Haxel 2012, p. 469). However, in neither case is it clear that such laws would withstand judicial review. In the US, there is a presumptive right to own a gun and exceptions to this rule are carefully scrutinized. Even should such legislation take effect, it is not clear how it could be enforced. Short of either total surveillance or a total ban on 3D printers, it is not likely that the government could ensure that individuals are not privately printing weapons in their garages. Total surveillance is worrying for a number of reasons, and banning 3D printing would have a chilling effect on innovation, as the printers have many legitimate uses.

Intellectual property

One conceivable result of the proliferation of 3D printing technology is that patent holders and manufacturers may attribute a drop in revenues to CAD file sharing and printing. If so, they may mimic the Recording Industry Association of America’s (RIAA’s) strategy and sue home downloaders. According to Wilbanks, RIAA has seen some long-term benefits that could be attributed to its litigation efforts—including its continued relevance under new economic models like iTunes (2013). On this account, RIAA’s lawsuits decreased the amount of file sharing, dissuaded some casual downloaders, and contributed to changing public perception of downloading. CAD files themselves are not patentable, nor are they typically subject to copyright protection. However, it is plausible that iTunes would have succeeded even without RIAA’s litigious behavior, and it is also possible that RIAA’s lawsuits had a chilling effect on innovation in the area of file formats and sharing/purchasing models. In addition, RIAA’s reputation has suffered as a result of going after home users. As Troxler and van Woensel describe the situation in the early 2000s:

technically speaking, everybody copied illegally, but the scale of downloading and sharing and copying was such that enforcement was hardly an option. Apparently the majority of people wanted something else… It only makes sense to talk about enforcement when a small minority of a population are offenders (2013, p. 202).

Although there are significant differences between copyright and patent law, the example of the music industry should serve as a cautionary tale for owners of intellectual property and regulators who seek to protect them. Several options are open to both parties, including a wholesale rewriting of intellectual property law, changing patents to work more like copyright, relieving 3D printer manufacturers of possible ‘contributory infringement’ suits, and providing explicit safe havens for filesharing websites that meet certain reasonable criteria.

In this section, we focus primarily on intellectual property law in the context of individuals who download designs from online repositories and those who share their designs through such repositories. We expect that larger enterprises will be well aware of the legal issues entailed by intellectual property law and that they will have the resources and foresight to deal with it appropriately. On the other hand, the hobbyist ‘do-it-yourself’ (DIY) community is unlikely to have the expertise or resources to ensure that their works do not infringe someone else’s intellectual property. Before the Internet enabled anyone with a connection to share plans with others, DIYers had less to worry about regarding potential violations of patents or other intellectual property, especially if their creations were for personal use. Any incidental violation would be unlikely to be discovered and would in any case be unlikely to cause the patent holder any serious harm. It would not be worth prosecution. Once plans could be shared over the Internet, however, both the discoverability and perceived deleterious effect of infringement grew. IP owners could search the same filesharing databases as DIYers, and often such databases publish download statistics, making it trivial for IP owners to estimate damages. This situation poses a real threat to DIYers. A person uploading a design that infringes on another party’s intellectual property puts downloaders of the design at risk, since any realization of the design would constitute infringement. Likewise, individuals who download an infringing design, make their own modifications, and upload the result (a common occurrence on DIY websites) would also infringe. Furthermore, uploading an infringing design also puts the hosting site or service at risk, since under certain circumstances they can be held liable as ‘contributory infringers’ for providing the means for its users to infringe. Without clear guidelines setting out the legal situation for all such parties, intellectual property law has the potential to chill innovation, expending resources in fighting legal battles instead of creating. Further complicating the issue, digital files travel with ease past national boundaries, but intellectual property laws differ from one jurisdiction to the next. Here, we focus again on the US context, mainly because more has been written there. (For an excellent review of IP in the UK/EC context, see Bradshaw, Bowyer, and Haufe 2010 and Bradshaw 2013.)

Let us first consider the issue from the point of view of the owner of intellectual property. 3D technologies make it easier to copy existing designs. This puts virtually everything at risk of infringement. In the past, the difficulty of copying complex designs was an effective protection even without explicit legal protection. 3D printers create complexity with ease, obviating that contextual protection. In the past, communicating the plans for a piece of machinery required a degree of skill and technical literacy that was simply beyond the average DIYer, or else required the use of expensive software that was outside of the budget of hobbyists or even small firms. Now, basic versions of such software is available for free. To make matters worse, patents on most useful items are never sought, because applying requires resources that could be spent elsewhere and because it is expected that infringement would be unlikely to cause substantial harm and because the protection is temporary. (See chart, below, outlining the requirements for patents.) Now, 3D technologies and Internet communications have transformed the landscape for intellectual property holders. The music and movie industries have already gone through a period of upheaval that has dramatically changed the profitability and outlook of former powerhouses. As 3D technology improves and becomes more widespread, makers of material things will face increasing pressure from infringers. It would be best to anticipate the coming changes, learn from the experiences of the music industry, and create clear guidelines that will protect intellectual property owners without freezing innovation.

Some action can be taken under current laws. For example, copyright can help to the extent products are duplicated for their aesthetic appeal rather than function. The unauthorized copying of a decorative figurine is a violation of copyright. Barraclough (2012) suggests that incorporating trademarks into the exterior design of an object can also strengthen claims of IP, even for functional objects (Barraclough 2011, p. 25). But in many cases, copyright and trademark protection simply do not apply, and patenting may be the only recourse for protection of intellectual property (see the chart below for some differences between the two).

A potential protection for manufacturers is design patents. While functional patents protect inventions that are new, useful, and non-obvious, design patents protect new, original, and ornamental designs. As Weinberg (2010) points out, design patents are very limited in scope, applying only to truly novel, completely non-functional designs. Moreover, “the design protection itself only extends to the actual design represented in the patent application, not similar designs or designs merely derived from the original” (Weinberg 2010, p. 9). The automotive industry has successfully used design patents for ‘body panels, lights, and mirrors … to prevent third parties from entering the auto replacement parts market’ (Weinberg 2010, p. 10). Similar reasoning might allow manufacturers to seek design patents that would protect against the sharing of home-brew repairs of manufactured goods, including knobs, handles, or other distinctive components.

A complication is that, ‘under existing law, the distributors of digital representations of products are not “making,” “selling,” or “using” the patented products or any “component” thereof’ (Brean 2013, p. 771). That is, in most cases, it is not until the object is actually printed out that any violation has occurred. In the abstract, it should be easy to prove infringement: the making of any patented object without authorization constitutes direct infringement. Likewise, distributors who knowingly provide plans that allow its customers to make protected objects would be liable through the doctrine of contributory infringement. But without pervasive, invasive surveillance, it is not clear how intellectual property owners could identify every violator.

Given the central case of the paper, it is worth noting, with respect to DIYers seeking patent protection for their creations, that there are restrictions on the sort of items that can be patented. In particular, many jurisdictions prohibit the granting of patents for objects against the ‘ordre public and morality’. In principle, this could dissuade some designers from attempting to create new firearm designs because any profit incentive would be diminished by a lack of patent protection. However, most DIYers do not seek patent protection for their works in the first place, and in the specific case of Cody Wilson, the idea of preventing copying and remixing of the Liberator design is contrary to its raison d’etre. (We thank an anonymous reviewer for bringing this aspect of patent law to our attention.)

The disanalogy to music files. Music files are copyrightable because they are creative works. 3D files squeeze in between copyright and patent: in general they are not violations of copyright because they are not copies of an existing plan—they are created based on the object itself. And they are not patentable because they merely describe a (potentially) patentable object. They are not themselves functional objects. Courts have resisted the argument that the sale of schematics constitutes infringement (see Brean 2013, p. 792).

In the US, the contributory infringement doctrine was established to ‘provide for the protection of patent rights where enforcement against direct infringers is impracticable’ (Aro Mfg. Co. v. Convertible Top Replacement Co., 377 U.S. 476, 511 (1964) (quoting H.R. 5988, 80th Cong., 2d Sess. (1948); H.R. 3866, 81st Cong., 1st Sess. (1949)). See Brean 2013 for discussion). If a 3D file repository were to engage in the willful and knowing distribution of plans for patented objects, they would be liable. Repositories typically have user agreements in which users agree that they will not upload such files, but this is not enough to indemnify the repository from liability in cases of active inducement to distribute plans for protected objects.

The Digital Millennium Copyright Act (DMCA) provides a practicable mechanism for copyright holders to stop the distribution of copyrighted works through online repositories. DMCA provides a ‘safe harbor’ for repositories that they meet certain requirements. Repositories must block or take down content that is identified in a notification of infringement from a copyright holder. If they comply with such requests, then they are not liable as contributory infringers. DMCA also protects repositories from liability from users by requiring a ‘counternotification’ mechanism for reinstatement of materials that do not in fact violate copyright. There has been some criticism that DMCA tends toward abuse, with copyright holders demanding takedowns in cases where they have no valid copyright claims. Perhaps because of the power difference between large copyright holders and individual users, most such claims result in the indicated materials being removed. Despite such abuses, the system has resulted in greater certainty for copyright owners, online service providers (including repositories), and users who violate copyright (intentionally or not). (For much more about DMCA in the context of 3D printing, see Doherty 2012.)

So far, there have been no court cases involving copyright and 3D printing. However, the website Thingiverse has instituted a DMCA-style takedown notification system in response to an incident involving the 3D design of a Penrose Triangle. On 27 January 2010, Dr. Ulrich Schwanitz created a 3D printable ‘Penrose Triangle’ that creates the visual experience of an optical illusion: a two dimensional drawing of an ‘impossible figure.’ He began to sell this object on Shapeways (a print-to-order website). Based on a video Schwanitz created, Thingiverse user Artur Tchoukanov worked out how the design worked and created his own version, which he uploaded to Thingiverse. Schwanitz sent a DMCA takedown notice to Thingiverse, alleging that ‘[t]he electronic models ‘Penrose Triangle by artur83’, located on your site at http://www.thingiverse.com/thing:6456 and ‘Penrose Triangle Illusion by chylld’, located on your site at http://www.thingiverse.com/thing:6474’ infringed on his copyright (this incident is described in detail in Rideout 2011.)

Thingiverse removed the objects, although Schwanitz subsequently relented to pressure to drop his complaints and the objects are now available on both Thingiverse and Shapeways. It is worth mentioning that some community members and some legal experts have suggested that Thingiverse was hasty in its recognition of the DMCA takedown request. Tchoukanov created his file based on a video of the object, not on Schwanitz’s file, so it is not clear that copyright applies. Moreover, courts have not established whether CAD files are more like computer programs (giving computers instructions) or blueprints (specifying a plan for construction). The former have been deemed copyrightable, while the latter are not.

| Copyright | Patent |

| Covers artistic, creative works | Covers useful articles |

| Automatically protects a work upon fixation | Must be applied for |

| Work does not have to be new to society | Work must be new to society |

| Lasts for the life of the author plus 70 years after death | Lasts for 20 years |

| Law assumes damages for infringement | Must prove damages from infringement |

(From Weinberg 2013b, 3).

A variety of legal scholars have considered the potential of 3D printing to disrupt the current legal equilibrium with respect to intellectual property law. Here we will briefly catalog six major suggestions. The first three of these suggestions target courts and legislative bodies. Two suggestions target the community of ‘DIYers’ or ‘Makers.’ A final suggestion applies to traditional manufacturers and owners of intellectual property.

1. Clarify the distinction between legal ‘repair’ and potentially infringing ‘reconstruction’

Patent law has a built-in exception allowing consumers a ‘right of repair.’ However, this right is limited. Consumers do not have the right to reconstruct an entire patented item (Wilbanks 2013, p. 1149). (See Donald S. Chisum, Chisum On Patents § 16.03[3], at 16-449 to -450 (2012). § 16.03[3], at 16-449 to -450; F. Scott Kieff et al., Principles Of Patent Law: Cases And Materials 1093 (5th ed. 2011).)

Unfortunately, courts have not created a bright line distinguishing cases of legal ‘repair’ and infringing ‘reconstruction’. Wilbanks makes three proposals that would greatly clarify matters:

(1) if the entire device is not copied, it is not reconstruction.

(2) shift the burden of proof ‘if the defendant simply explains that he or she was only replacing what was necessary to preserve the object’s life, or shows that any part is different from the actual patented combination, the burden would automatically shift to the plaintiff’ (Wilbanks 2013, p. 1177).

(3) Make explicit Brennan’s list of tests or considerations for determining the line between repair and reconstruction: the intent of both the patent holder and the user and the life, importance, and cost of part replaced in relation to patented whole.

2. Expand Copyright (or Patent) Law

Another approach to revising intellectual property law in light of 3D printing and other emerging technologies would be to expand copyright or patent law. Lawmakers could explicitly eliminate the safe harbor, which would open filesharing sites to liability, and likely many would shut down. This would likely have a chilling effect on innovation, but lawmakers may decide that threats to traditional manufacturers would be even more costly. Along similar lines, lawmakers could forbid the creation of 3D files based on 3D scans of physical objects. However, this would be ‘inapposite to copyright law as it could deprive the public of the ability to make use of a tool capable of non-infringing uses’ (Rideout 2011, p. 174). Indeed, our own lab uses 3D scans of residual limbs as a basis for quickly creating low-cost prosthetics. It would be a shame to cut off this and other promising lines of research.

3. Provide an explicit safe harbor

Lawmakers concerned with encouraging 3D printing and other emerging technologies could take another tack: explicitly providing a safe harbor for repositories of 3D designs in the style of DMCA. The inclusion of patents in addition to copyright raises at least one new challenge. Many repositories of useful items enable users to ‘fork’ (copy and modify) items already in the repository. This allows users to combine and alter existing designs while maintaining a ‘heredity’ or credit connection to past objects. If a parent object is taken down as a result of DMCA takedown notification, must all descendants be taken down as well? It is not clear that this is always the case, since a modification could remove the infringing features of the parent item. Some kind of review mechanism appears to be required to decide cases like this on an individual basis.

4. Create a defensive patent system

Schultz and Urban propose a defensive patent system to address concerns of various ‘Open Innovation Communities’ (OICs)—including those that have grown up around hobbyist 3D printing. While OICs have legitimate concerns about the current patent system stifling innovation, Schultz and Urban argue that new legal structures have the potential to defray their concerns while furnishing the protections traditionally associated with patents (Schultz & Urban 2012).

5. Community Self-Policing

The current model for most 3D design sharing sites is a version of open source hardware, similar to open source software. On this model, creators cede ownership to the community, sometimes with specific restrictions, for example, requiring that their authorship be recognized, their code or designs be used only for noncommercial products, or that any ‘fork’ or alteration of the design be itself shared with the community. However, “Creative Commons licenses do not cover an instance where a design from outside the 3D printing community is copied without permission and then shared. The 3D printing community needs to decide how to deal with this situation before more DMCA complaints are filed” (Rideout 2011, p. 176). Thingiverse has instituted a DMCA policy for this very purpose. But communities need to be cautious and informed about the way such systems work to ensure that frivolous takedown notices are rejected and creativity is not hampered.

6. Proactive corporate strategies

Corporations wishing to avoid the mistakes of RIAA and major music labels have several options, including:

(1) strengthening their IP by incorporating trademarks into the exterior design of products, making them harder to scan and copy;

(2) licensing generously and early in order to stay in control of files; and

(3) selling designs simply and conveniently to encourage consumers to “do the right thing” (see Barraclough 2011 for additional detail and further advice for companies worried about infringing behavior).

Conclusion

In this paper, we have recounted our experiences in creating a version of Cody Wilson’s Liberator 3D printed gun and we have analyzed some of the disruptive implications of increasing availability of emerging fabrication technologies for regulation and regulators. We introduced a conceptual framework allowing us to assess the technological possibilities afforded by 3D printers and their effects on the ‘regulatory landscape.’ 3D printing promises to upend traditional manufacturing by making complex, precision objects easy to produce, making plans easy to distribute, and making the means of production easy to own. Yet the prospects for regulating 3D printers themselves are limited, because like their 2D namesakes, 3D printers are general purpose machines with many legitimate functions. This changing technological infrastructure poses an increased regulatory challenge. We have described how formal regulation works in tandem with contextual factors including technical, economic, ethical, and social constraints on action. We argue that 3D printing—and other emerging, potentially disruptive technologies—are often able to skirt or obviate existing regulation because those regulations assume that contextual factors will remain constant. We conclude with two cautions and one recommendation for policymakers.

First, recognition that current firearm and IP regulations rely on contextual factors could prompt policymakers to seek new regulations that do not rely on contextual factors. We suspect that this is not possible, and certainly not practical. In the case of firearms in the US, the effectiveness of current regulations depends in part on the difficulty of making regulated parts. Before 3D printing, precision frames were difficult to make without expensive, difficult-to-acquire machining equipment. Therefore, regulations focused on the means of producing the guns. Now that 3D printing and Internet-enabled sharing of plans is beginning to open up the means of production to wider publics, those regulations will lose some of their force. However, new regulation that avoids any connection to the realities of how guns are designed, manufactured, and distributed will be a nonstarter.

Second, we caution policymakers to avoid laws that would put the brakes on disruptive innovation. Laws that, for example, restrict access to 3D printers or that require plans to be reviewed before being printed might have the desired effect in their own jurisdiction, but would have no effect outside of it. And as we have seen, design plans now flow easily from one jurisdiction to another, and even home-brew 3D printers are now capable of making complex objects entirely hidden from view of authorities.

Instead, we recommend that policymakers create regulatory frameworks that explicitly define the goals as well as the specific regulatory apparatus. This should allow lawmakers to more easily measure the efficacy of a given law, identify contextual defeaters, and inspire innovative regulatory solutions that are more responsive to changing technological and social contexts. Care must be taken to construct laws that respond to concerns raised by the advent of 3D printers without being so narrow as to apply only to 3D printers. As Easterbrook (1996) argues with respect to regulation of the Internet, ‘error in legislation is common, and never more so than when the technology is galloping forward. Let us not struggle to match an imperfect legal system to an evolving world that we understand poorly. Let us instead do what is essential to permit the participants in this evolving world to make their own decisions’ (Easterbrook 1996, pp. 215-216).

For 3D printing in general, we submit that regulators should take great care not to stifle innovation by hastily closing down file-sharing sites or regulating access to 3D printers. However, there are several areas where legal language could be clarified to foster innovation. For example, IP laws could be revised to explicitly allow 3D design repositories the ‘safe harbor’ status they are hoped to have. Legislation could also clarify liability issues with respect to the user, seller of printed products, printer, distributor of plans, or creator of plans. And intellectual property laws could be re-written to more clearly designate which aspects of a 3D plan fall under patent or copyright protection. This approach takes advantage of existing community norms and would dissipate some of the uncertainty that dampens innovation.

In the specific case of 3D printed guns, we argue that the central concern for the present should be the distribution of plans, not the capability of available 3D printers to create guns. This is because the guns 3D printers can currently make aren’t very effective and do not pose a serious danger to the public, whereas the easy distribution and remixing of plans could quickly lead to improvements of 3D printed firearms. Assuming that rapid improvement of 3D printable firearm designs is what authorities want to prevent, the most effective solution may be to follow the model of ‘contributory infringement’ and ‘contributory negligence’ laws. Such regulations could target (1) the systems that enable the sharing of firearm designs, thus encouraging those systems to self-police and remove such plans, and (2) the designers of firearms themselves at precisely the point their actions pose a danger to the public: when they share those designs with others. The ‘contributory’ approach would have the advantage of being less invasive than targeting individual 3D printers directly by requiring that every plan be monitored, and it would not conflict with the right of individuals in the US to create firearms for personal use. Lawmakers would need to be careful to target only those who are actively attempting to share firearm designs, and not other designers whose inventions are adopted or remixed by firearm designers. We predict that such measures could discourage innovation around gun design, while letting other innovation run free.

Emerging technology is disruptive and often complex, but lawmakers (and repository website policymakers) could do more to make the situation clearer, which should serve to encourage appropriate innovation, protect the rights of innovators and owners of intellectual property, and create a clear, fair process for adjudicating disagreements.

References

Ashcraft B 2014. ‘Japanese Man Arrested for Having Guns Made with a 3-D Printer’, Kotaku, 8 May 2014, available from: http://kotaku.com/japanese-man-arrested-for-having-guns-made-with-a-3d-pr-1573358490 [Accessed: 10 December 2014]

Barraclough, E. 2011. ‘A five-step strategy for the 3D revolution’, Managing Intellectual Property, No. 214, pp. 24–27.

Berman, B. 2012. ‘3-D printing: The new industrial revolution’, Business Horizons, Vol. 55(2), pp. 155–162. doi:10.1016/j.bushor.2011.11.003

Bradshaw, S. 2013. ‘3D printing legal update’, Computers and Law, Vol. 24(2), pp. 31–34.

Bradshaw, S., Bowyer, A. and Haufe, P. 2010. ‘The intellectual property implications of low-cost 3D printing’, ScriptEd, Vol. 7(1), pp. 5–31.

Brean, D H 2013. ‘Asserting patents to combat infringement via 3D printing: it’s no “use”’, Fordham Intellectual Property, Media & Entertainment Law Journal, Vol. 23(3), pp. 771–814.

Bump, P 2013. ‘No Assembly Transpired: What We Learned from Failing to 3D-Print a Gun’, The Wire, 21 May, available from: http://www.thewire.com/national/2013/05/novices-need-not-apply-what-we-learned-trying-and-failing-3d-print-gun/65460/. [Accessed: 6 December 2014]

Campbell, M 2012. ‘Absolutely fabricated’, New Scientist, 216(2895), pp. 46–49. doi:10.1016/S0262-4079(12)63206-0

Doctorow, C 2013. ‘3D printed guns are going to create big legal precedents’, The Guardian, 13 May, available from: http://www.theguardian.com/technology/2013/may/13/3d-printed-guns. [Accessed: 6 December 2014]

Doherty, D 2012. ‘Downloading infringement: patent law as a roadblock to the 3D printing revolution’, Harvard. Journal of Law & Technology, Vol. 26, pp. 353–403.

Easterbrook, F H 1996. ‘Cyberspace and the Law of the Horse’, U. Chi. Legal F., p. 207.

Finocchiaro, C W 2013. ‘Personal factory or catalyst for piracy? The hype, hysteria, and hard realities of consumer 3-D printing’, Cardozo Arts & Entertainment Law Journal, (Spring), pp. 473–508.

Guston, D 2013. ‘Understanding “Anticipatory Governance”’, Social Studies of Science, available from: http://sss.sagepub.com/cgi/doi/10.1177/0306312713508669 [Accessed 10 March 2014].

Hornick, J and Roland, D 2013 ‘3D printing and intellectual property: initial thoughts’, The Licensing Journal, Vol. 33(7), pp. 12–16.

Ivanova, O, Williams, C, and Campbell, T 2013. ‘Additive manufacturing (AM) and nanotechnology: promises and challenges’, Rapid Prototyping Journal, Vol. 19(5), pp. 353–364. doi:10.1108/RPJ-12-2011-0127

Jensen-Haxel, P 2012. ‘3D Printers, Obsolete Firearm Supply Controls, and the Right To Build Self-Defense Weapons Under Heller’, Golden Gate University Law Review, Vol. 42(3), pp. 447-495

Kolbe G 2000. ‘The Making of a Rifled Barrel’, FirearmsID [online], available from: http://firearmsid.com/Feature%20Articles/RifledBarrelManuf/BarrelManufacture.htm [Accessed: 10 December 2014]

Kyriakou, H, Englehardt, S and Nickerson, J V 2012. ‘Networks of Innovation in 3D Printing’, SSRN Scholarly Paper, Rochester, NY, Social Science Research Network, available from: http://papers.ssrn.com/abstract=2146080 [Accessed 7 February 2014]

Lee, E 2012. ‘Digital Originality’, Vanderbilt Journal of Entertainment & Technology Law, Vol. 14(4), pp. 919–957.

Lessig, L 2006. Code v. 2: Code and Other Laws of Cyberspace, Basic Books: New York. Available http://codev2.cc/download+remix/Lessig-Codev2.pdf

Lipson, H. 2011. ‘This will change everything’, New Scientist, 211(2823), p. 20. doi:10.1016/S0262-4079(11)61821-6

Litton, P 2007. ‘“Nanoethics”? What’s New?’, The Hastings Center Report, 37(1), pp. 22–25.

‘Man held on suspicion of owning guns made with 3-D printer’, Japan Times, 8 May 2014, available from: http://www.japantimes.co.jp/news/2014/05/08/national/politics-diplomacy/man-arrested-for-possessing-guns-made-with-3-d-printer/#.VI-5Tb-0Lwx [Accessed: 10 December 2014]